Call Us: 855.266.5676 | 954.684.0218

Email Us: info@curtisstokes.net

Call Us: 855.266.5676 | 954.684.0218

Email Us: info@curtisstokes.net

by Jim Healy

Cruising south in 2017, I became aware that my house water pump was cycling on and off at random intervals. I proceeded to change our water pump head/valve assembly, but that repair action attempt left the symptom unaffected. After a period of vigorous self-denial, I had no choice but to accept that I must have had a slow leak somewhere in the house potable water system.

Sanctuary is a 1988 Taiwan-built trawler. Many boats built in the period were fit with polybutylene (PB) plumbing and PB plumbing fittings. PB water line “pipes” are gray in color, somewhat flexible, and the fitting are gray plastic. Our PB system was marketed under the trade name of “Qest.” Aboard Sanctuary, our potable water plumbing is 3/8” diameter tubing, which means 3/8” ID (inside diameter) and 1/2” OD (outside diameter). The system fittings are, therefore, either 3/8” by 1/2” MPT (Male Pipe Thread) or 3/8” by 1/2” FPT (Female Pipe Thread).

In the 70s through early 90s, PB systems were used in many building, RV and boat applications. When it became clear that PB fittings failed as they aged, there was a Class Action lawsuit settlement called COX v. Shell Oil et al. to compensate PB installation failures in installations between January 1, 1978 through July 31, 1995. The defective PB fittings were discontinued and the product removed from the market. Today, replacement Qest fittings of “better” materials are available as replacement parts from a variety of sources, including big box stores, ACE Hdwr and many Internet vendors.

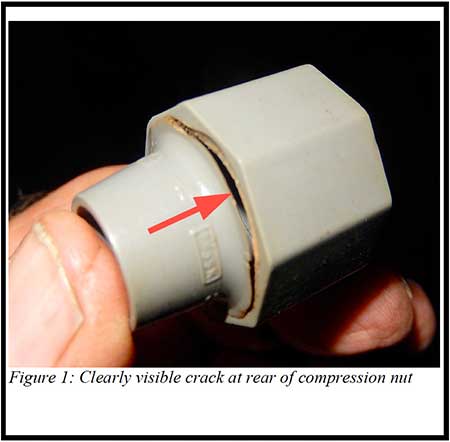

My leak was in the cold water feed to our galley and aft cabin shower, in a predictably inaccessible location. In my search for the leak, I furthermore identified two non-leaking fittings with visible cracks in the body of the compression nut. The leakeI had planned to replace two nuts and have some spares. I wound up using five of those six nuts as I worked on the system.

DO NOT OVER-TIGHTEN THESE NUTS; no more than one-quarter turn past hand tight.

By Jim Healy from his Blog Travels of the Monk 36 Trawler, Sanctuary

Disclaimer: Curtis Stokes and Associates does not necessarily agree or promote the content by the above author. This content is to be used only with the reader’s discretion.

© 2024 Curtis Stokes & Associates, Inc. | All rights reserved.